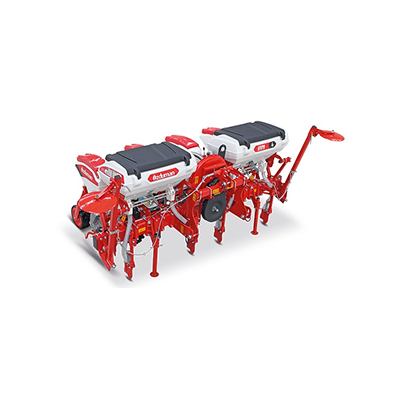

Pneumatic Seeder Tine Shared (HVM)

Description

This machine which is called pneumatic precision sowing machine, is an agricultural machine which is driven only by cardan shaft and PTO shaft of the tractor and works with hydraulic lifting unit of the tractor and universal 3-point hanging system.

You can perform precision sowing and sow different kinds of seeds into all kinds of cultivated soil types with this equipment. Sowing machine operates with the help of a pneumatic system and can be equipped with various accessories such as additional sowing units such as a fertilizer tank. The most important feature of the sowing machine is the ease of use as well as the simplicity of its design.

Sowing unit ensures that all kinds of seeds can be sown one by one in every soil condition due to double disc for maximum efficiency, ie. without wasting seeds.

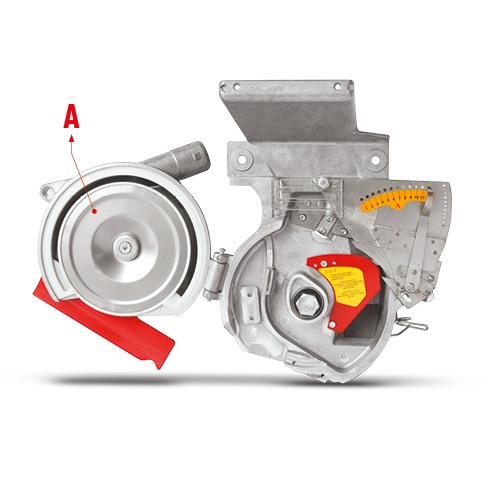

A - Unit Cover

Unit Cover

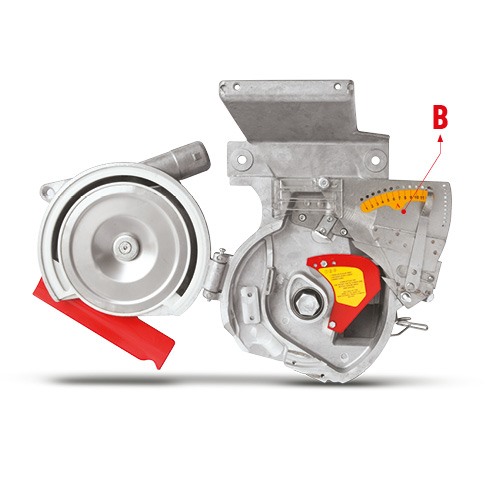

B – Coarse adjustment

It is a system built in the sowing unit, which allows seeds to fall on the soil one by one precisely.

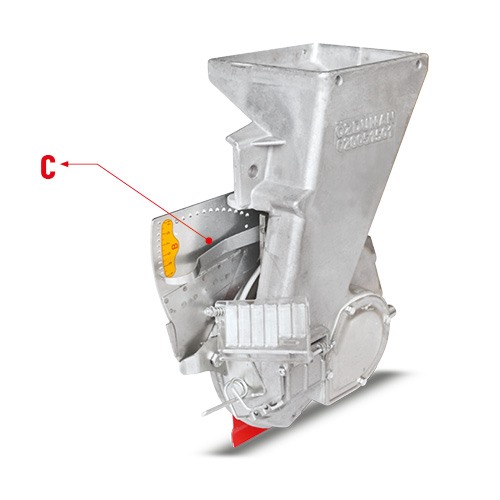

C – Precision Setting

It is a system built in the sowing unit, which allows small seeds to fall on the soil one by one precisely.

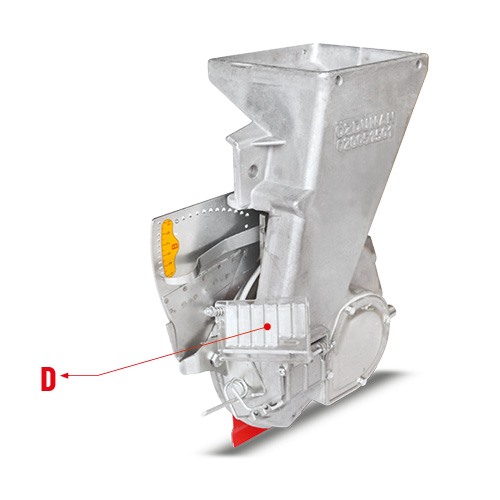

D – Observability

There is an observation window to monitor regular adhesion of the seed disc and seed.

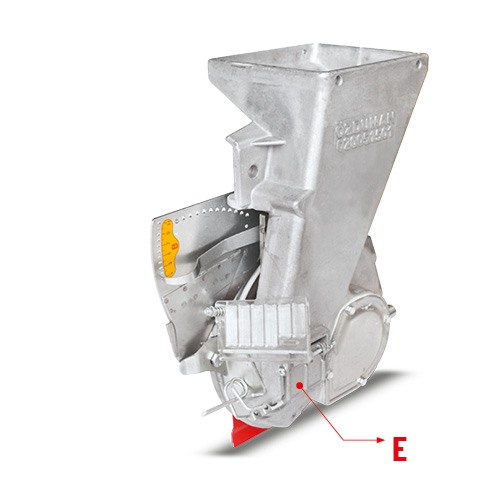

E – Seed Cleaning

It provides easy cleaning of the remaining seeds in the tank at the end of sowing and while changing the seed.

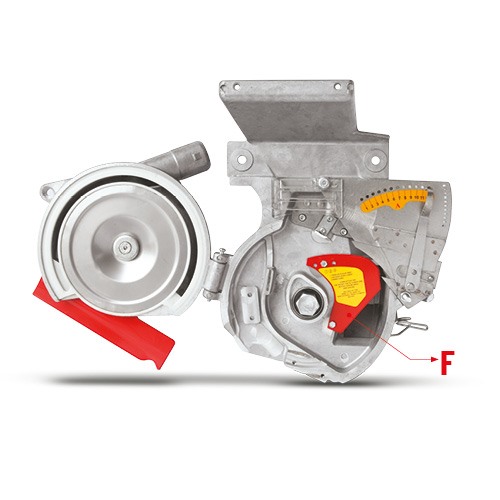

F - Curtain

Seed flow control cover can be adjusted in different positions. Width of the seed entrance channel is adjusted and it prevents excess seed from overflowing from the distributer. This cover may need to be adjusted for the slope of the land or for small seeds.

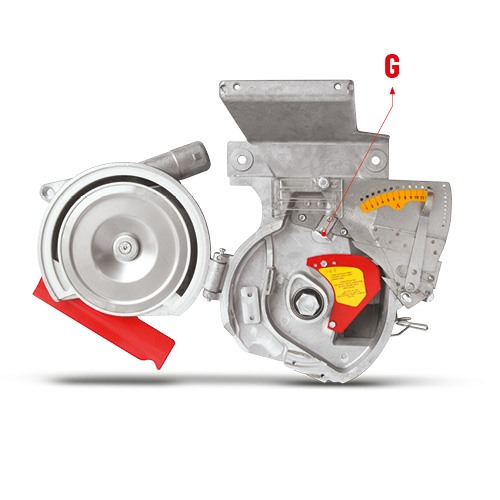

G - Precision Thrower

It prevents sticking of different sizes of seeds on the disc as double and guarantees that double seeds don’t fall on the soil.

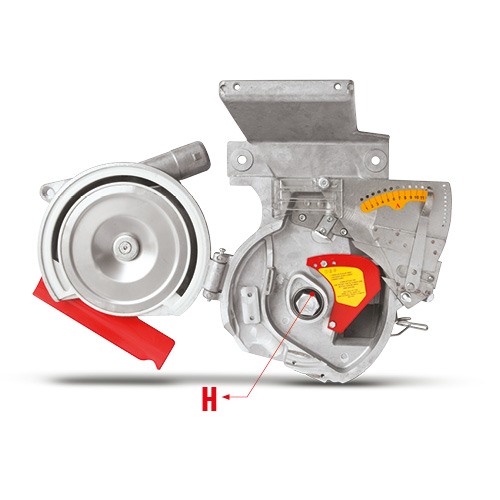

H - Stable Bearing

It allows the disc to turn without pausing thanks to bearing placed in sowing unit.

A – Parallelogram

By copying the soil surface with the help of steel arms, it allows the seeds to fall to equal height.

B - Covering The Seed

They are mounted on the right and left sides of the sowing leg and cover the seed to prevent losing temper of the soil which is opened for sowing seed by sowing leg.

C – Seed Soil Contact

It is made of alloy steel and it is resistant to breakage and abrasion. Thanks to its V shape, it forms a smooth sowing line and helps to open V shaped seed bed suitable for heavy soil conditions.

D – Preliminary Preparation For Seed Sowing

It cleans the area in front of the sowing leg by scraping soil and clods in front of the sowing leg in the field which is sown and it performs ground preparation for sowing.

E – Seed Tank

55-liter seed tank with a large volume is used for each seed variety.

F –Depth Adjustment

It provides adjustment opportunity to sow various seeds in different.

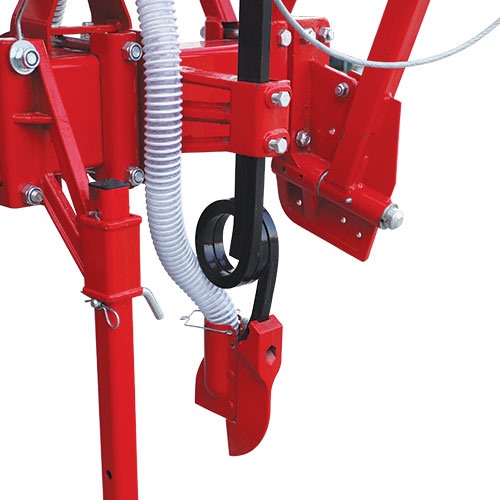

G – Pressure Spring

A force must be created on the ax so that the sowing unit ax can open a groove on the soil. This pressure should be reduced or increased depending on different soil types. Pressure is increased due to this system.

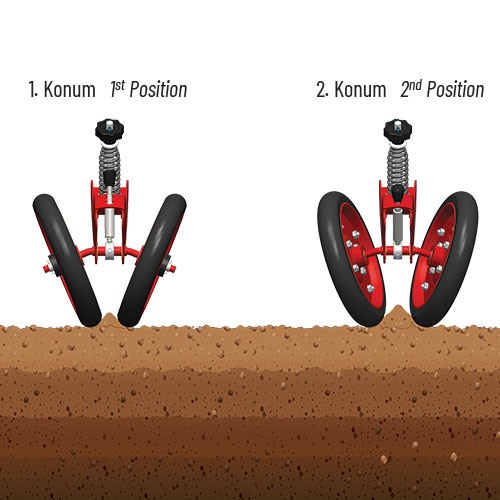

H – Closer Wheel

Rear wheel closes seed grooves with different settings without hardening and enables covered seed to come out of soil easily.

I – Unit Lock

To increase unit spacings for sowing technological seeds, it allow the unit to be disconnected without changing the machine design.

J – Continuous Sowing

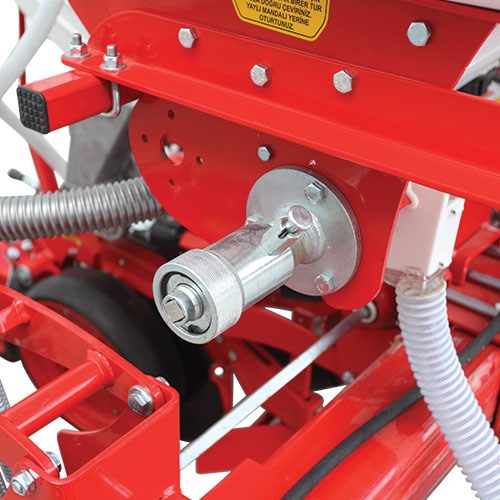

Drive shaft which doesn’t require maintenance, which has unit cancellation system and safety pin against forcing, guarantees a proper sowing.

Seed Drop in Axe Type Seeding Unit

Thanks to the seeding unit which is axe type performs succesfull planting in all conditions especially in stony conditions. Depending on the small or coarse seed types, upon request can be installed different sizes of axe seed bed openers. Cast axes are made of special alloy steel casting material which will not wear easily.

Rear wheel closes seed grooves with different settings without hardening and enables covered seed to come out of soil easily.

V-type pressure wheel has 3 settings which are “press, width and crossness” and each can be adjusted individually. By throwing dry soil to direction where seed will come out, it prevents formation of duff or in other words, duff layer on the soil to a certain extent.

Fixed Chassis

Machine’s center of gravity is close to the tractor. It is easy to lift the machine while turning during sowing. Row spacing change is done manually.

CLOSER WHEEL

Rear wheel closes seed grooves with different settings without hardening and enables covered seed to come out of soil easily. V-type pressure wheel has 3 settings which are “press, width and crossness” and each can be adjusted individually. By throwing dry soil to direction where seed will come out, it prevents formation of duff or in other words, duff layer on the soil to a certain extent.

CAST WHEEL WITH NOTCHED SHEET

It provides ideal usage in the less cultivated land having stems due to its closing feature.

CAST WHEEL

It provides ideal usage in the less cultivated dry land due to its closing feature.

FAN

Seeds are enabled to adhere to the disc with vacuum effect. In this way, adhered seeds are enabled to drop on the line opened at the desired intra-row distance. Fan absorbs by means of the vanes on it by being driven by PTO shaft of the tractor.

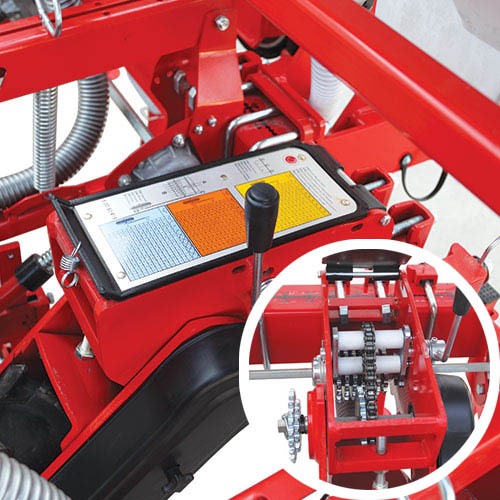

TRANSMISSION

In order to make intra-row setting, there is a drive wheel on the machine with transmission. You can easily adjust row spacing of the seed you want to sow with the help of gears.

VACUUM METER

Different vacuum values are needed for various seed types and varieties you will sow. If you don’t set this vacuum value well, some problems occur. If you set low vacuum value, you may encounter problems such as failure of seeds to hold on to the disc or if the vacuum value is too high, the disc may stick to the seal because of overloading and cause motion wheels to turn difficultly. To make this value visible, vacuum meter is placed on the fan.

DAMPER

Motion wheels move with friction force. It disrupts wheel’s contact with the ground on poorly cultivated lands which are not smooth, causes wheel jamming and disrupts sowing precision. Damper adjustment enables the machine to steepen or become closer to the ground. Adjustment of damper makes sliding into soil easier for the machine and prevents the wheel from dragging. To prevent this, wheel is manufactured as articulated and tensioned with spring. There is a stop bolt on the articulated point where the wheel is connected in order to enable the wheels to operate in the same range.

TURBO DISC

Turbo discs placed in front of the discs in 330 mm diameter and in front of tearing discs in heavy soil conditions, play an important role in the preparation of suitable seed beds.

DEPTH WHEEL HAVING HOLES

It prevents clogging of tearing discs in high moist and clay soil and allows regular sowing.

GARBAGE CLEANER

Garbage cleaner placed in front of the tearing disc in land with stems, scatters stems to the right and left sides and brings the seed together with the soil.

SEED PRESSURE WHEEL

After the seeds falling from the seed groove, fall on the seed bed, it applies pressure on them and brings them together with the moist soil It is effective for especially coated seeds. Thanks to the scraper on the wheel, it prevents the seeds and soil from sticking on the wheel.

FERTILIZER DISCHARGE COVER

Discharge covers for fertilizer tank cleaning

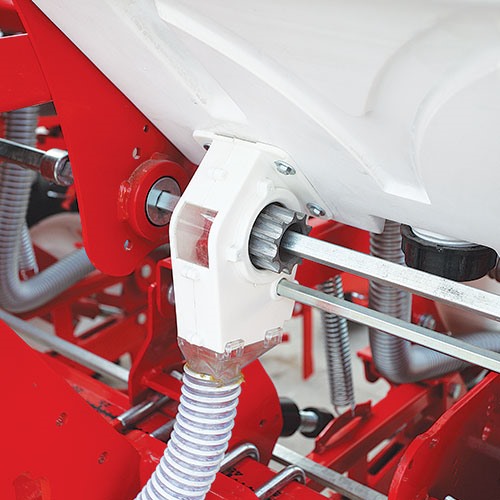

HELICAL GEAR

Sluminum helical gear which ensures continuous spreading of fertilizer

SIEVE

Sieve system that prevents fertilizer from jamming

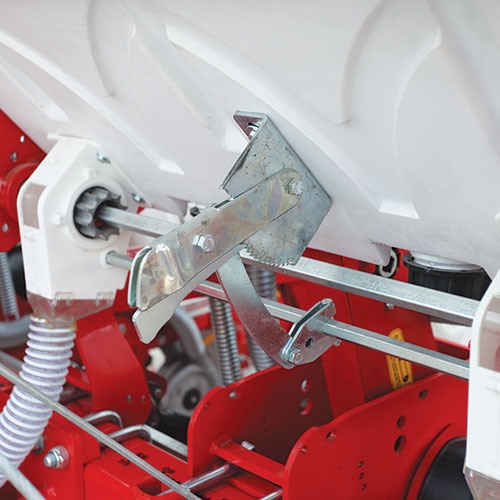

FERTILIZER ADJUSTMENT LEVER

Fertilizer adjustment lever is available to adjust fertilizer spreading rate.

FERTILIZER DISCHARGE LEVER

There is a fertilizer discharge lever on fertilizer tank. Fertilizer should be discharged completely after sowing is completed, otherwise fertilizer distributors may set as the fertilizer will oxidize. This is made to eliminate this and facilitate discharging operation.

SPRING AX LEG

In order to provide proper fertilizer spreading for roughly prepared soil, self-spring ax leg is placed.

DISC FERTILIZER LEG

For roughly and precisely prepared soil types, it opens fertilizer bed with a double disc and forms a suitable fertilizer bed.

INDEPENDENT HYDRAULIC MARKER

It provides easy use thanks to the independent hydraulic marker attached to the machine depending on the user’s request.

DECARE METER

It allows to measure the sown land digitally in decares.

FRONT PRESSURE WHEEL

Pressure wheel is on the front side of the sowing unit. It provides the balance of the unit together with the soil scraper and closer wheel and ensures that sower ax does not rise above the ground much.

Note: Pressure wheel is only used for sowing beets. It can be mounted on the machine if desired.

SOWING CONTROL DEVICE

By controlling seeds falling from the units during sowing and by informing the unit in case of failure at the same time, it provides controlled sowing.

TRAFFIC SET

By making the machine manufactured in different working widths visible, it provides safe transportation.